White annealed wire: the spool of wire that fits in one hand

Always putting people at the centre of its corporate responsibilities without making any compromises: this is a point of honour for Bottaro which, also in the production of the BWC™ white annealed wire spool, pays attention to the health and safety of all operators in the sector.

In this article we would be discussing:

- A white annealed wire spool for every need

- Bottaro docet: how to optimally produce and package BWC™ white annealed wire

- The BWC™ spool: a few numbers that make all the difference

- All the advantages of a human-scale spool of wire

A white annealed wire spool for every need

The BWC™ (Bottaro Wire Construction) is a small spool of white annealed wire that can meet the needs of various user categories such as construction companies, industry, private individuals, retailers, craftsmen and hardware stores.

This broad target group already shows the great versatility of a product that fits easily in one hand due to its small size.

Easy to use and extremely resistant, the Bottaro spool owes its great commercial success to the material it is made of: white annealed wire.

Of higher quality than black, this material is cleaner and more valuable, as well as softer. Its greater malleability is able to improve the quality of the operator’s work, reducing fatigue and some health risks.

Bottaro docet: how to optimally produce and package BWC™ white annealed wire

To the consumer who might wonder whether BWC™ white annealed wire is really quality wire, Bottaro responds with strict control over the entire production chain, which begins with the careful selection of top-quality European wire rod and ends with an environmentally friendly, ISO:9001-certified production process (read more here).

But that’s not all, because Bottaro has implemented an impeccable production cycle, in which, every second and for every centimetre of wire produced, it is controlled by robotic instruments capable of stopping the process the moment they detect any defect.

It is precisely the use of automation that makes it possible to avoid human error, as the operator never touches the product manually, which is also good for his own safety.

Likewise, such a refined production process is able to ensure that the product has both the typical softness of BWC™ white annealed wire and, thanks to an annealing cycle controlled with special probes, its high strength.

BWC ™ white annealed wire is also ideal in the packaging phase of the spool: after being wound, the spool is covered with a polyethylene film with Bottaro graphics or even anonymous, which is heated by a special device so that it adheres perfectly to the spool, preventing it from springing back once it has cooled down so that there is no risk of cutting the operator’s hands.

A further advantage of this film is that it insulates the wire from contact with the air, preserving it from rust and corrosion.

The BWC™ spool: a few numbers that make all the difference

Small, versatile and light – that’s how you can describe the BWC™ white annealed wire spool in just three words.

Here, however, is how to explain the same spool in more technical but equally practical terms:

- Weight: only 330 g (25 kg the box of 75 pieces, 1,000 kg a whole pallet)

- Thickness of wire: 0.90 mm to 1.40 mm

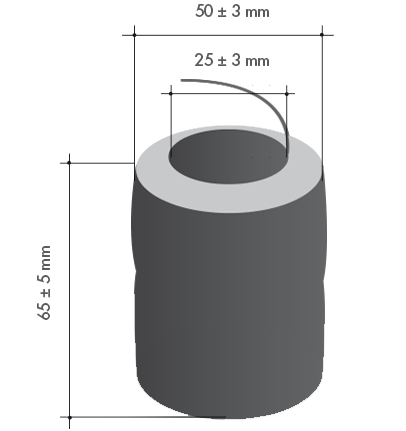

- Spool diameter: 50 ± 3 mm

- Spool height: 65 ± 5 mm

- Number of strands in the spool: 1 to 3 strands depending on the variant chosen by the customer

All the advantages of a human-scale spool of wire

But what are the advantages of these specific features for the operators who will be using the spool?

Let’s look at some of them:

Health and transport

The low weight of the single spool is ideal for the health of the operators. This is because, in daily work, it avoids all the problems associated with handling heavy loads, which is one of the causes of spinal and muscular disorders.

The 75-piece box also has its advantages, not only because the 25 kg weight of the package remains below the weights that are risky for the spinal column and can be easily handled even by operators belonging to protected categories, but also because it is a format that allows optimising shipments, facilitating handling and storage in 1000 kg pallets, which, once they arrive, can be easily dismantled and sorted.

Safety and time saving

The small size of the spool allows the operator to carry one or more spools without problems of weight and space, even fitting them into the tool belt. How does this help the worker on the construction site?

On a road construction site, for example, the truck carrying the material may not be in the vicinity of the work site. Retrieving more wire means having to walk a long way, often with traffic. Similarly, on a construction site, which is usually overhead and several storeys high, it means moving at dangerous heights and between reinforcing bars.

These simple examples demonstrate how reducing the movement of workers on site helps to improve their efficiency and reduce their fatigue, both of which are effects derived from the use of the spool that allows time to be optimised and reduces the risk of accidents, all to the benefit of safety.

Versatility and practicality

The thickness of the wires and the possibility of choosing between 1, 2 or 3 wires in the spool allows the spool to be used to its full potential, making it extremely functional for all the company’s needs. It is possible to opt for the single-strand spool or for the double-strand spool if a greater thickness is required. The three-strand spool, on the other hand, is ideal for those who need to tie at maximum strength.

Once again, therefore, Bottaro, with a product that combines safety in the workplace, attention to the health of operators and excellent performance, proves to be able to effectively intercept the needs of its customers and their employees, distinguishing itself from the competition for continuous innovation always at the service of the person.

© Copyright Bottaro Mario S.r.l. - All rights reserved