Complete guide to using Bottaro’s High-Tensile Galvanized wire

In the recovery and recycling industry, the use of high-quality materials is critical to ensure efficient and safe work processes. BWR™ GalvaHT represents the ideal solution for those seeking superior performance and uncompromising reliability. In this article we will look at how to obtain the best and revolutionize your work through the proper use of Bottaro High-Tensile Galvanized wire.

In this article, we will discuss:

- Bottaro technicians’ report

- What is BWR™ GalvaHT and why choose it

- How to use Bottaro’s High-Tensile galvanized wire?

- Benefits of optimized wire use

- Committed to excellence in recycling

Bottaro Technicians’ Report

Thanks to constant interaction with clients worldwide, Bottaro’s technicians have often identified improper use of the product engineered for the recycling and recovery sector, the High-Tensile Galvanized wire. Incorrect use of the wire leads facilities to not fully exploit the wire’s potential, resulting in reduced efficiency and productivity of baling presses.

Field experience therefore prompted Bottaro to come up with a solution that would help everyone in the industry understand how to use Bottaro’s High-Tensile Galvanized wire and get the most out of their recovery and recycling facility. Thus was born this guide, accompanied by an informative video with all the practical guidance useful to those who use BWR™ GalvaHT every day.

What is BWR™ GalvaHT and why choose it

The wire BWR™ GalvaHT or High-Tensile Galvanized wire, is the product that Bottaro offers to the recycling market that uses double RAM presses. This wire has been designed for the most challenging pressing applications thanks to its strength and elongation.

BWR™ GalvaHT – like many other Bottaro products intended for the recycling and recovery sector – is used in over 50 countries worldwide and approved by the most important industry associations, including Federec, ISRI, and National Waste and Recycling Association.

Customers and associations unanimously support the reasons why choosing BWR™ GalvaHT (and many other company products) is optimal:

- Strength and durability: Bottaro’s High-Tensile Galvanized wire is designed to withstand the pressing operations of many materials, thanks to its strength and elongation capacity;

- Process optimization: adopting Bottaro wire allows optimizing packaging and recycling processes, increasing productivity, and reducing waste and downtime.

- Complete support: Bottaro offers top-level customer service (fast logistics, multilingual commercial support, etc.) as well as a wide range of resources, including detailed guides and video tutorials, to ensure a positive experience and maximum satisfaction for the customer.

How to Use Bottaro’s High-Tensile Galvanized wire?

Before using the High-Tensile Galvanized wire, it is essential to follow some precautions to ensure not only safety in use but also to maximize the efficiency of the product.

This section offers a step-by-step guide and a video tutorial that cover everything important to know for preparing, cutting, and correctly positioning the wire, minimizing risks and optimizing use in packaging and recycling applications.

Phase 1: Preparation

Maintaining the protective plastic: It is crucial to keep the protective plastic on the wire until the moment of use to protect the product from harmful elements such as rain and moisture. This simple but essential step ensures that the wire’s quality remains unchanged until its use.

Phase 2: Cutting the Protective Sheath and Metal Straps

Correct cutting of the plastic and metal straps: Using a utility knife, you can remove the protective plastic and cut the metal straps. These operations require attention to prevent damage to the wire and must be carried out with care, protecting hands and eyes from possible injuries and ensuring personal safety.

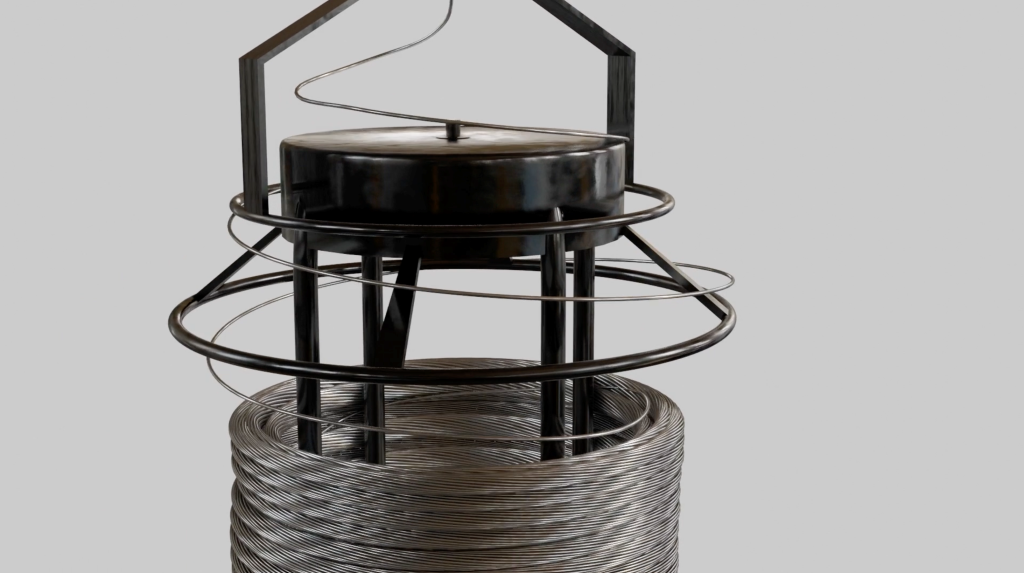

Phase 3: Positioning the Coil on the Baling Press

Correct positioning on the Baling Press: Properly placing the wire on the press is essential to prevent performance issues, ensure perfect wire unwinding, avoid interruptions, and improve the efficiency of the packaging or recycling process.

The correct placement of the coil under the press is done in three steps:

- Bring the upper guide ring closer to the lower ring (the hat one)

- Ensure that the upper ring is aligned straight and has no defects (for example, a bent or broken ring).

- Position the stand on the axis perpendicularly.

Safety Details and Injury Prevention

During all work phases, it is essential to follow some safety precautions:

- Protection during cutting: make sure to use the appropriate personal protective equipment, such as gloves and safety glasses, when cutting the protective plastic and metal straps. This not only protects from accidental cuts but also prevents eye injuries from flying particles.

- Checking the integrity of the wire: before using the wire, it is important to check that there are no visible damages or defects. A damaged wire can compromise the safety and efficiency of the packaging or recycling process.

- Clear instructions for all operators: ensuring that all operators are adequately trained on the correct procedures for using and maintaining the high-strength steel wire is fundamental to maintaining a safe and productive work environment.

Benefits of optimized wire use

As highlighted by our technicians, correct and optimized use of High-Tensile Galvanized wire for recovery and recycling brings several advantages to users:

- Maximum productivity: correct positioning and use of High-Tensile Galvanized wire reduce machine downtime and increase the productivity of packaging and recycling operations.

- Increased safety: following the guides and tutorials that accompany the product, not only optimizes the use of the wire but also increases safety for operators, reducing the risk of injuries related to non-compliance with correct usage procedures.

- Quality of work: using Bottaro’s steel wire in the most effective way ensures that the plant and workers’ work is not only productive but also of superior quality, thanks to the reduction of problems related to improper use of the material.

Committed to excellence in recycling

Through this guide and the new video tutorial, we want to demonstrate commitment to innovation and continuous improvement, highlighting our goal to provide not only high-quality products but also complete support that helps our customers achieve the best possible results.

We thank all our technicians for their continuous work in analysis and support to companies that choose Bottaro wire, and to our customers for their willingness to provide constructive feedback that allows us to continually raise the quality bar of our products and services.

© Copyright Bottaro Mario S.r.l. - All rights reserved