BWG: the only specific wire for Hot-Dip Galvanizing

Our BWG was presented to various world associations of the sector in 2017 and it received a unanimous market response: the BWG wire fully meets the demands of the global market.

The real difference between our BWG wire and other common wires

In the past, the selection criteria for purchasing wire was exclusively related to an economic evaluation and this product was considered in most cases as a pure commodity. Furthermore, the possibility of easily find black annealed wire from every corner in the world, thanks also to the market distortions by the Chinese, led many people to consider interchangeable the different types of wire.

However, the quality of a wire can be very different and at Bottaro we truly believe in this statement. For this reason we decided to invest in a wire with a higher quality in order to significantly distinguish ourselves from the competitors. Our BWG wire is a scientific product, the result of the multi-annual collaboration with our customers and technical committees of the major international associations, of which we are member and supporter.

Hereunder you’ll find more information about the quality and the target of a wire that reformed the galvanizing routine.

Our BWG objectively improves production performances

Our BWG wire was developed with the primary goal of improving galvanizers’ productive performances and thanks to its mechanical characteristics, we have achieved a very satisfactory results: the use of BWG wire increases the production of a single turn of work up to 30%.

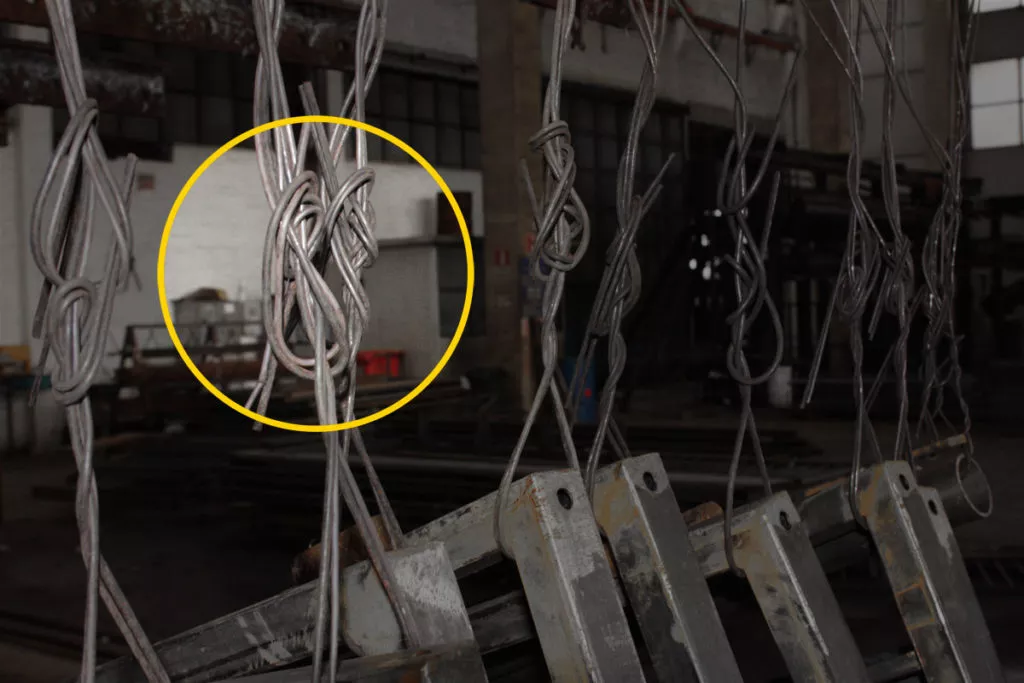

Moreover, thanks to the extraordinary malleability, it is possible to opt for a bigger diameter of the wire and reduce the number of wires used for each binding, decreasing the size of the knot and consequently the buildup of zinc and generating an economical saving throughout the production process.

Safer workplaces and higher quality at work

Our Bottaro Wire Galvanizing is a revolutionary product also in another way. Through the use of this particular item designed by Bottaro, we received appreciation also as regards the improvement of the quality of the work.

First of all, technical offices choose BWG wire for its malleability since it eases their work and preserves them from the risk of inflammation of the upper limbs. Second, the exceptional mechanical properties of our BWG wire significantly raise the safety threshold in galvanizing units helping companies to gain departments in line with the regulations and train well-qualified and competitive workforce.

The improvement of the mechanical characteristics of this product contributes to improve working environments and worker’s life quality, reducing dramatically sick-leave due to overwork and inflammation of the joints and improving the company’s output.

Experience and science for a safe and efficient hot dip galvanizing process

At Bottaro we believe in the combination of quality and safety and for this reason, since the beginning, we invested in materials research to achieve the highest standards that science could make available. In fact, we provided many resources to expertise in order to finally find a product that would meet all safety and productivity needs of the galvanizing industry.

Latest discoveries financed by Bottaro

2000 – In order to ensure a constant quality of all straightened wires, in 2000 our engineers developed a project of Ing. Bottaro Alberto, for the robotized production of cut to length wire. Many tests and continuous improvements in all stages of the production process led to the final completion of the project in 2014, making our company the only one in the world with a robotized production process of cut to length wire.

2006 – During its 50th anniversary of activity, our company presented its first official study of the performances of the BWG wire on the occasion of the INTERGALVA meeting in Naples (Italy). The study was conducted in collaboration with Zinco Service and AQM and followed in all phases by Dr. Mario Ubiali Ph.D., a renowned technician in the entire galvanizing industry. It has been an instrument to communicate for the first time the existence of a specific wire designed specifically for the hot dip galvanizing industry.

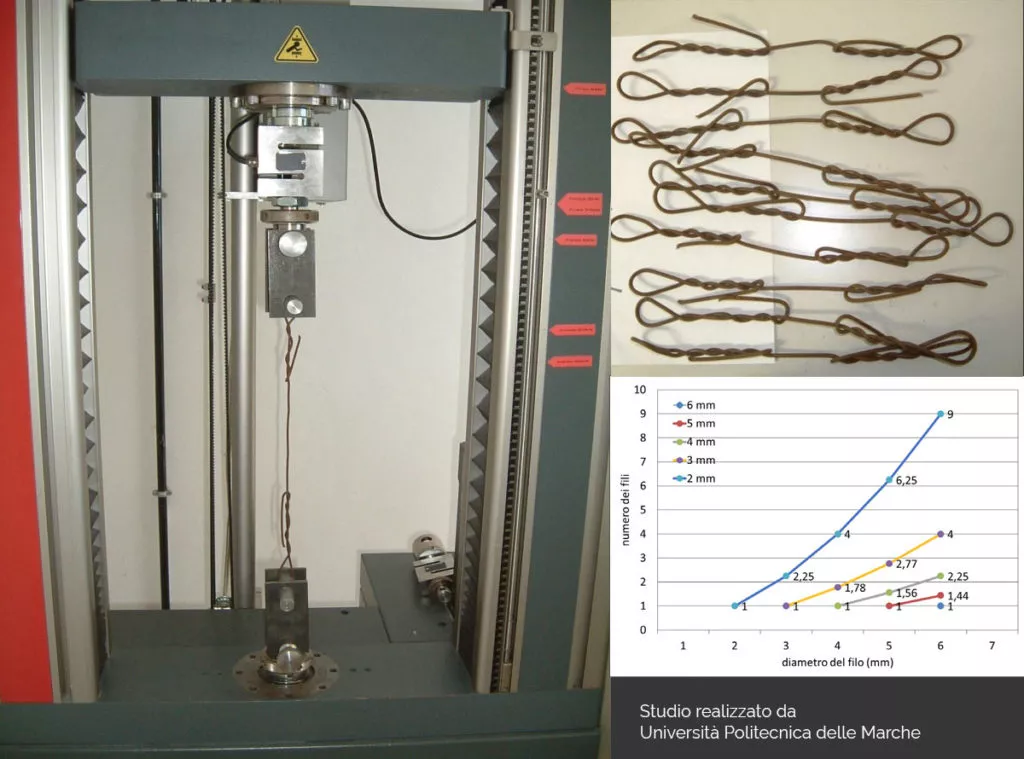

2015 – In this year we took another step forward with the aim to stand out in the market. On the INTERGALVA edition held in Liverpool, the second study on our BWG wire, conducted by the Department of Industrial Engineering of the Polytechnic University of Ancona under the direction of Prof. Fratesi, a luminary on metallurgy and hot dip galvanizing, was world premiering. In particular, three main features were deepened:

- The rating of the zinc adherence on wires according to the chemical analysis of the wire used.

- The mechanical strength as a function of the number of wires used for tying and of their diameter.

- The rating of stability of the ties performed by operators in function of the applied load

BWG is the new reference standard for the hot dip galvanizing market

The choice to invest in the product, to collaborate with technicians and universities, and to put to good use the experience gained in this sector allowed us to test the material from many points of view and to check all production stages. We managed to define a wire standard that allowed our customers’ safety officers to develop acceptance and threading tabs for hooking, indicating the correct tensile strength and elongation ranges, necessary to define the wire usage and to ensure the respect for all safety aspects.

Prevention and protection responsible staff have therefore a valid and certified tool that takes into account all the variables that can be encountered during the hot dip galvanizing process. In conclusion, it is clear that all the research and analysis made for the design of the BWG wire make our wire a unique product that cannot be replicated on the market and something completely different from any other wire proposed by other manufacturers or retailers in the world. Therefore our company BOTTARO, thanks to the creation of the BWG wire, remains firmly a world-renowned leader of this industry.

Although this, we never stop, we always stay alongside our customers and their technicians in order not to exclude new room for further improvement.

Would you like more information on our studies?

We can provide you with the results that we obtained in these years investing resources and finances. We kindly ask you to fill in the fields hereunder to receive a copy of the technical study made in collaboration with the Polytechnic University of region Marche and consult the test results.

[contact-form-7 id=”466″ title=”Request Technical Studies”]

© Copyright Bottaro Mario S.r.l. - All rights reserved